In Istanbul Döküm, casting simulations are made by technological applications by considering the customer demands and needs, possible errors and critical points are determined and the casting process is realized without any lapse.

In the laboratory of Istanbul Döküm, for all productions, chemical analysis, mechanical yield – tensile – elongation tests, and when required hardness tests, UT, MT and MPI tests are provided.

In line with the pattern demand, the technical drawings are given to the pattern shop in our structure or to the pattern manufacturers we have been working for years. Pattern measurements are reported to our customers and after approval, to be taken to the following mold.

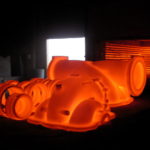

Cast iron, nodular iron, steel, stainless steel, bronze, duplex, super duplex and aluminum sand casting production is done in our foundry.

Istanbul Döküm has hand moulding system. Alfacet and Carbon Dioxide resins are used with mixer which has 10 tons capacity sand output per hour.

Istanbul Döküm is an organization, has flexible production methods enable to cast, iron, nodular iron, steel, stainless steel, duplex, super duplex and bronze in sand molding system in a single foundry. Our foundry, as different from the hundreds of foundries across Turkey and Europe, complex is equipped to supply castings to customers.

In our induction furnaces, your orders are casted carefully with our qualified personnel.

Casting cleaning is carried out by a separate team within our structure and some parts are subjected to heat treatment in accordance with special demands. We apply heat treatment in order to achieve better mechanical values depending on the end use areas.

Sandblasting is done in our 2500x2500x3500(h)mm inner dimensioned sandblasting machine with a single piece capacity of 10 tons.

Depending on the demand of the customer, premachining and final machining, are done in our own machining shop and in the companies we have been cooperating with for many years.

Shipments are prepared with appropriate packing, according to customer demands.

Comments are closed.